- All

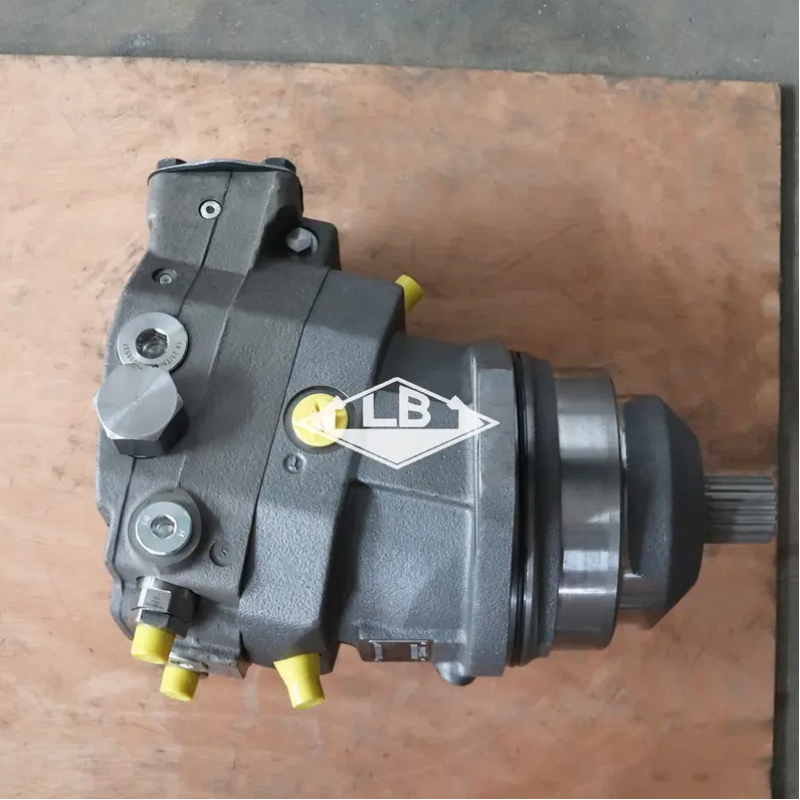

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-11-10 Origin: Site

Downtime and costly repairs can derail even the most tightly run operations, especially when a critical component like a travel gearbox malfunctions. At LB, we supply precision-engineered travel gearbox parts that not only replace worn components but also prevent the most common failure causes, keeping tracked machinery running longer and more reliably. Understanding why these gearboxes fail is the first step toward reducing unexpected maintenance costs and ensuring maximum uptime. With the right components and knowledge, operators can avoid unplanned service interruptions and optimize machine performance in demanding environments.

A travel gearbox is a fundamental component in tracked machinery, responsible for transferring engine power to the tracks efficiently. Without a properly functioning travel gearbox, machines like excavators, bulldozers, and other heavy-duty earth movers cannot move effectively or handle loads safely. This component is not just a connector—it is the heart of motion for tracked vehicles, multiplying torque and ensuring smooth, controlled movement across varied terrains. Poor gearbox performance can result in higher fuel consumption, increased wear on adjacent components, and slower operational cycles, all of which add to operational costs.

Understanding a travel gearbox begins with its internal structure. The primary elements include planetary gears, a ring gear, and a pinion. Planetary gears distribute load evenly, while the ring gear transmits torque to the output shaft. Seals prevent hydraulic fluid and lubricant contamination, and bearings reduce friction and support rotational motion. Each of these parts must function harmoniously, as even minor wear or misalignment can escalate into a full failure. In addition, the housing and mounting points ensure structural integrity under heavy load, providing a stable environment for the internal components to operate efficiently.

The travel gearbox multiplies the torque generated by the engine, allowing tracked machines to navigate slopes, push heavy loads, and maneuver efficiently on rough surfaces. By converting high-speed input from the hydraulic motor into slower, high-torque output, the gearbox ensures both power and precision. Any loss in this multiplication effect can result in sluggish performance, increased stress on other drivetrain components, and higher fuel consumption. Optimized gear ratios and robust construction allow machines to maintain consistent speed and performance under heavy operational stress.

Real-world experience shows that most travel gearbox failures fall into six main categories. Understanding these modes helps operators identify symptoms early and prevent costly downtime.

One of the leading causes of travel gearbox failure is hydraulic contamination. Dirt, water, or degraded oil can penetrate the system, damaging seals and bearings. Seal failure often starts with minor leaks, but unchecked, it allows abrasive particles to enter the gearbox. This contamination accelerates wear on gears and bearings, leading to noisy operation, vibration, and ultimately total gearbox failure. Preventive measures include using high-quality hydraulic fluid, inspecting seals regularly, and installing robust replacement seals when needed.

Gears endure constant pressure and cyclical loading. Over time, metal fatigue can form cracks in the teeth, and uneven wear patterns may develop. Symptoms include unusual noise, uneven movement, or slipping under load. Identifying tooth fatigue early allows for targeted replacement of worn gears rather than full gearbox replacement, saving both time and money. Advanced materials and precise heat treatment of LB gears increase fatigue resistance and prolong service life.

Bearings support the rotational movement of gears and shafts, reducing friction and heat. Lack of proper lubrication or the presence of contaminated oil can lead to overheating, pitting, and eventual bearing seizure. Once bearings fail, the gearbox may lock up or generate extreme noise and vibration, putting adjacent components at risk. Regular lubrication checks, proper oil viscosity, and using LB-approved bearing assemblies significantly reduce this risk.

Operating machinery beyond its design limits creates excessive torque and heat, stressing gearbox components. Thermal expansion and repeated overloads can warp gears, crack housings, and degrade seals. Overheating is often a silent killer—operators may notice performance degradation only after significant damage has occurred. Installing LB parts with improved thermal resilience and optimized load distribution reduces the likelihood of these failures.

Travel gearboxes require precise alignment during installation. Misaligned shafts or improperly torqued flange bolts can cause uneven loading, vibration, and premature wear. Even small installation errors are magnified under heavy use, leading to early failures that might otherwise be preventable with correct procedures. LB components are designed for precise OEM-fit installation, minimizing human error during replacement or assembly.

External factors such as moisture, debris, and corrosive environments can attack both the gearbox housing and its internal components. Corrosion weakens structural parts and accelerates fatigue on gears and bearings. Protective measures, including high-quality seals and robust materials, are essential for long-term reliability. Our upgraded housings and corrosion-resistant coatings ensure the gearbox maintains structural integrity even in harsh working conditions.

When a travel gearbox fails, the impact on operations can be severe. Machines may become immobile, leading to project delays and additional labor costs. Minor bearing damage might require a partial rebuild, but major gear or shaft failure often necessitates full replacement. Downtime can disrupt multiple projects simultaneously, amplifying costs. By selecting quality replacement parts, operators can extend intervals between repairs and reduce the likelihood of catastrophic failures. Investing in the right components now can prevent costly emergency downtime later, saving both time and money over the machine's operational life.

LB’s travel gearbox parts are designed to address the exact failure modes described above. Our components feature hardened gear teeth to resist fatigue, high-precision bearings for smooth operation, and improved seals that guard against hydraulic contamination. OEM-fit flanges ensure proper alignment, while optimized lubrication channels maintain consistent oil flow, reducing heat buildup.

A recent example from field service involved a mid-sized excavator fleet that had experienced recurring seal and bearing failures. After retrofitting LB travel gearbox parts, maintenance intervals doubled, and unplanned downtime dropped significantly, proving the effectiveness of our product enhancements. Operators also reported smoother track movement and quieter operation, which contributed to improved operator satisfaction and productivity.

Owners can take proactive steps to extend travel gearbox life. Key maintenance practices include:

Inspecting seals and housings for leaks or cracks

Monitoring hydraulic fluid quality and replacing contaminated oil promptly

Performing torque checks on flange bolts and mounting hardware

Testing bearings for smooth operation and excessive play

Regularly reviewing lubricant levels and conducting contamination tests

Observing gearbox temperature trends to detect early signs of overheating

Keeping the external gearbox clean to prevent debris-induced damage

LB provides complementary spare parts kits tailored to specific models, making these inspections and replacements straightforward and ensuring that critical components are always on hand when needed. Proper preventive care, combined with high-quality replacement parts, significantly extends the service life of the gearbox.

Deciding whether to repair, rebuild, or replace a travel gearbox depends on the extent of damage and operational demands. LB offers:

Remanufactured gearboxes for cost-effective replacement

OEM-equivalent parts for like-new performance

Upgraded components designed for longer service intervals

All our products are backed by support and warranty coverage, providing peace of mind while minimizing lead time and ensuring that machines can return to work promptly. Our team also provides technical guidance on maintenance schedules and compatibility with different machine models.

Understanding common travel gearbox failures and taking preventive steps with high-quality parts is the most effective way to maximize uptime and reduce maintenance costs. LB’s precision-engineered components address the root causes of gearbox failure, allowing machines to perform reliably even under heavy workloads. For operators seeking longer service life and lower repair risks, contact us today to source model-fit travel gearbox components and inspection support.

Q1: How can I tell if my travel gearbox is experiencing bearing failure?

A1: Common signs include unusual noise, vibration, and overheating. Early detection allows for targeted replacement of bearings before major damage occurs.

Q2: What maintenance practices help prevent hydraulic contamination in a travel gearbox?

A2: Regular inspection of seals, testing hydraulic fluid, and replacing contaminated oil promptly are essential practices.

Q3: When should I choose a rebuild versus a full replacement for my travel gearbox?

A3: Minor wear or seal failure may warrant a rebuild, while extensive gear or shaft damage usually requires full replacement with OEM-equivalent or upgraded parts.

Q4: How do LB travel gearbox parts improve service intervals?

A4: Our parts feature hardened gears, improved seals, and optimized lubrication channels, which reduce wear and extend the time between necessary maintenance.