- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2026-01-14 Origin: Site

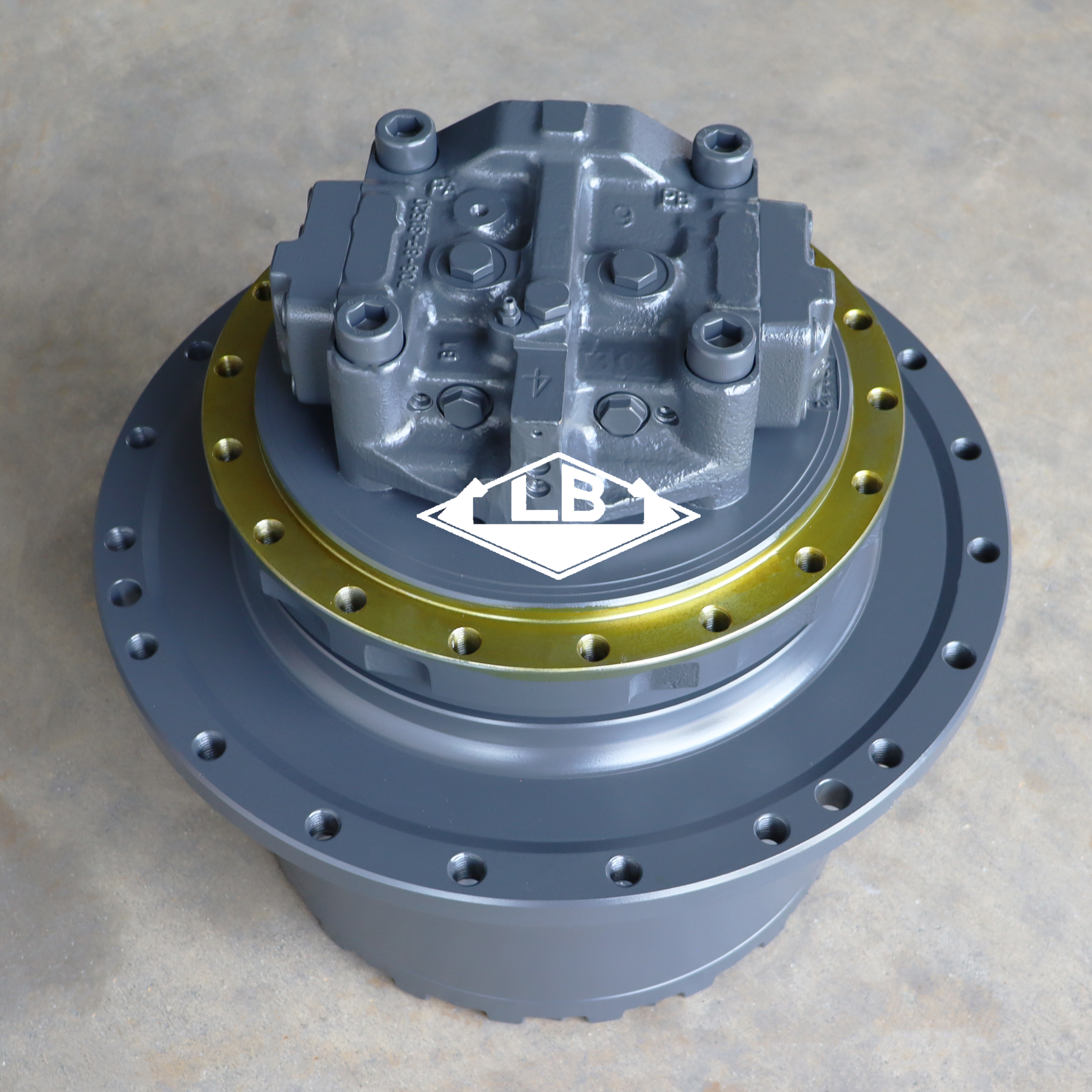

The final drive is a key component in your vehicle’s drivetrain, transferring engine power to the wheels. It operates under extreme pressure and temperature, making regular maintenance essential. Neglecting oil changes can lead to costly failures. In this article, we will discuss how often final drive oil should be changed and why it is vital for optimal performance.

The oil in the final drive plays a vital role in lubricating the gears and reducing friction. As the gears inside the final drive work under immense torque and high temperatures, the oil acts as a barrier to prevent them from grinding against each other and wearing down. Without proper lubrication, the gears experience excessive heat, which can cause them to seize or fail. This wear-and-tear process can lead to costly repairs, making regular oil changes an essential part of final drive maintenance.

The main purpose of the final drive oil is to reduce friction between the moving gears. When the oil starts to break down or get contaminated, it loses its ability to lubricate effectively, which can result in increased wear and overheating. Regular oil changes ensure that the gears continue to run smoothly and are protected from undue friction, allowing the final drive to function properly and extend its lifespan.

Regular oil changes are crucial for maintaining the internal components of the final drive. If the oil isn’t changed regularly, contaminants like metal particles, dirt, and debris can accumulate in the oil. Over time, this contamination can cause significant damage to the final drive’s gears and bearings. By changing the oil at regular intervals, you help prevent internal damage caused by these contaminants, ultimately extending the life of the final drive and saving money on premature repairs.

The frequency at which the final drive oil should be changed depends on several factors, including the machine's age, usage, and manufacturer recommendations. Most manufacturers provide guidelines on oil change intervals. However, general rules suggest changing the oil every 1,000 to 2,000 operating hours or at least once a year, whichever comes first.

It’s important to follow the operator’s manual for the recommended oil change frequency. Manufacturers typically suggest changing the final drive oil after 1,000 to 2,000 hours of operation, but this can vary based on the machine and its operating conditions. If the machine operates under extreme conditions—such as in muddy, wet, or hilly terrain—oil change intervals may need to be shortened.

For new machines, it is generally recommended to change the oil after the first 250 to 500 hours of operation. The reason for this is that new final drives often contain residual particles or metal shavings from the manufacturing process. This oil change helps to flush out these contaminants and ensure that the drive operates smoothly from the start.

Table: Recommended Oil Change Intervals for Final Drive

Usage Condition | First Oil Change (Hours) | Subsequent Oil Changes (Hours) | Frequency (Years) |

Regular Use | 250-500 | 1000-2000 | At least once a year |

Harsh Conditions (mud, water, steep slopes) | 250-500 | 500-1000 | At least once every 6 months |

Several factors can impact how often the final drive oil should be changed. These include operating conditions, environmental factors, and the type of machine.

Machines working in harsh environments—such as water, mud, or steep slopes—require more frequent oil changes. These conditions accelerate the breakdown of oil, as it gets contaminated more quickly by dirt, debris, and metal particles. If you are operating your machine in such conditions, you may need to reduce the oil change interval to ensure the final drive is properly lubricated.

It is also important to regularly inspect the oil for any signs of contamination or discoloration. If the oil appears thick, dirty, or has metallic particles, it may be time for an oil change, even if you haven't reached the recommended interval. This proactive approach helps detect any early problems before they become severe.

The type of oil used in the final drive is crucial for its performance. Most final drives require high-quality gear oils with specific viscosity grades. Typically, SAE 80W-90 or 85W-140 gear oils are commonly used, as they provide the necessary lubrication and protection for the gears under heavy loads and high temperatures.

These oils are ideal for final drives because they are designed to withstand high-pressure conditions. The viscosity of these oils ensures that the gears remain well-lubricated even under extreme stress. Choosing the right viscosity is essential to prevent overheating and excessive wear in the final drive.

The American Petroleum Institute (API) rates oils with various quality classes, and for final drives, the API GL-5 rating is commonly recommended. This rating indicates that the oil is suitable for extreme-pressure conditions, which is essential for the gears inside the final drive. Always use the oil recommended by the manufacturer to ensure optimal performance.

While it might be tempting to use engine or hydraulic oils for the final drive, these are not suitable unless specifically permitted by the manufacturer. Using the wrong type of oil can lead to poor lubrication, increased wear, and even failure of the final drive components. Always follow the manufacturer’s recommendations for the right oil to use.

Before beginning the oil change, it’s important to gather the necessary tools and equipment, such as wrenches, drain pans, and new oil. Also, ensure that the vehicle is on a level surface, and the final drive is cool enough to handle safely.

● Wrenches or socket sets

● Drain pan to collect old oil

● New final drive oil (matching manufacturer specifications)

● Protective gloves and safety equipment

Start by positioning the vehicle so that the final drive is level, then locate the drain plug. It’s crucial to remove the drain plug first, allowing the oil to drain fully. If the oil is warm, it will drain more easily.

Remove the drain plug and let the oil flow into the pan.

Dispose of the used oil responsibly, as it contains contaminants that could harm the environment.

Once the old oil has completely drained, replace the drain plug and add fresh oil into the fill plug. Use a funnel to avoid spillage and ensure the correct amount of oil is added. Most final drives will have a fill line indicating the proper oil level.

Slowly pour the new oil into the final drive until it reaches the proper level.

Check the level by removing the fill plug. If the oil begins to spill out, you’ve reached the right level.

After completing the oil change, it’s a good idea to inspect the oil that was drained. Look for metal particles or discoloration, which may indicate internal wear or contamination in the final drive.

Regularly inspecting the oil and maintaining proper levels is key to ensuring the longevity of your final drive. Make it a habit to check the oil at least once a month or as recommended by the manufacturer.

Always check for oil leaks, contamination, and unusual discoloration.

Inspect the final drive housing and seals regularly to ensure no oil is escaping.

Over time, oil can degrade, especially under harsh operating conditions. If you notice that the oil is no longer clear, or if it has become thick or gritty, it may be time for a change.

Keep the oil at the correct level to ensure smooth operation of the final drive. Too little oil can cause friction and overheating, while overfilling can lead to leakage and excessive pressure inside the system.

Maintaining the final drive by changing the oil regularly is crucial for keeping your machinery running smoothly and preventing expensive repairs. Following manufacturer guidelines and performing timely oil changes can significantly extend the life of the final drive. At Jiangmen Liba Machinery Co., Ltd., we offer high-quality aftermarket parts, including final drive oils and components, to help ensure the performance and longevity of your machinery at an affordable cost.

A: Final drive oil should generally be changed every 1,000 to 2,000 hours or at least once a year.

A: Regular oil changes prevent gear wear, overheating, and oil contamination, ensuring smooth operation of the final drive.

A: Neglecting oil changes can lead to overheating, gear damage, and even final drive failure, resulting in costly repairs.

A: No, final drive oil requires specific gear oils like SAE 80W-90 or 85W-140, different from engine oils.

A: In harsh conditions, oil should be changed more frequently, typically every 500 to 1,000 hours, depending on use.