- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-11-21 Origin: Site

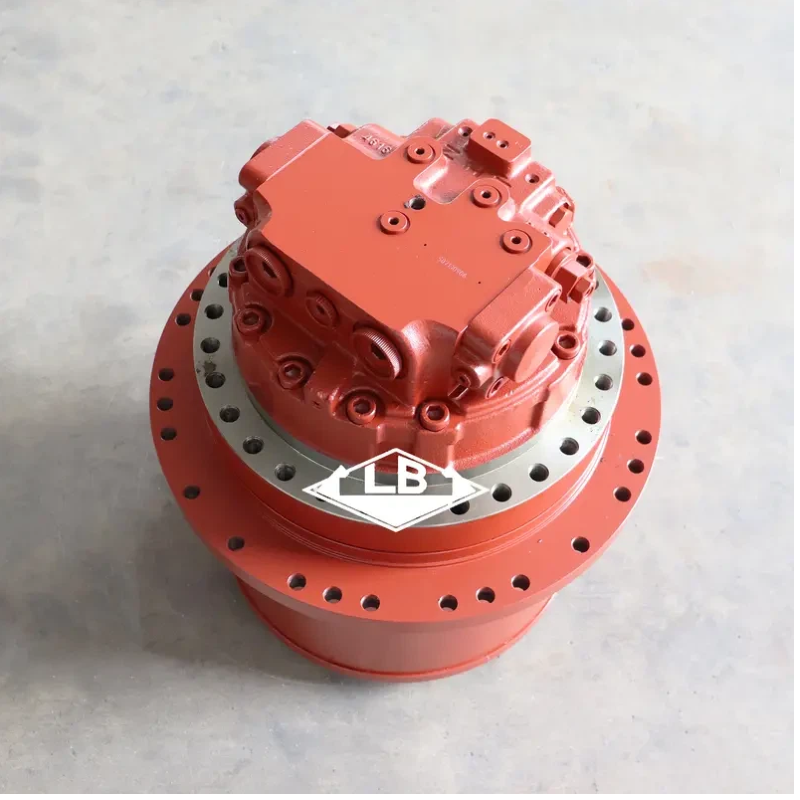

When it comes to heavy-duty earth-moving machinery, every component plays a role in maintaining efficiency and reliability, but few are as crucial as the travel gearbox. This component governs the machine’s movement, translating engine power into controlled motion across challenging terrains. Choosing the right travel gearbox can significantly reduce stalling, improve traction on uneven ground, and allow operators to complete tasks faster while maintaining safety. At LB, a leading manufacturer and supplier of travel reducers and swing reducers, we specialize in producing high-quality travel gearboxes designed to perform reliably under even the harshest conditions. By investing in superior travel gearboxes, fleet managers and site operators can achieve measurable improvements in both operational efficiency and overall project timelines.

On construction and earth-moving sites, inefficiencies often originate from travel drive problems. Track slippage is one of the most common challenges, especially in muddy, wet, or uneven terrain. When tracks lose traction, machines burn more fuel, wear down components faster, and operators struggle to maintain consistent speed, causing delays in project completion. Slow travel speeds under load are another critical concern. Machines carrying heavy attachments, large quantities of material, or operating on steep gradients often struggle to maintain optimal speed if the gearbox cannot handle high torque demands. This results in reduced productivity, higher fuel consumption, and extended project timelines.

Frequent stops due to overheating, worn seals, or internal component failure further compound the problem. Every unplanned stop interrupts workflow, reduces efficiency, and increases the risk of project delays. Additionally, unpredictable failures can escalate downtime costs, forcing operators to wait for repairs and leaving machinery idle. These issues highlight the need for a reliable, high-performance travel gearbox that can withstand heavy loads, harsh conditions, and prolonged use without compromising reliability.

Choosing the right gearbox also has a direct impact on operator confidence. Operators working on challenging sites need equipment that responds predictably and consistently. A high-quality travel gearbox provides smoother control, reduces the likelihood of sudden stalls or slowdowns, and ultimately allows the operator to focus on the task rather than on managing machinery problems. This combination of reliability, efficiency, and operator confidence drives measurable improvements in productivity across any jobsite.

Not all travel gearboxes are created equal, and certain technical specifications directly influence performance and productivity. Among the most critical are:

Torque Margin: The ability to handle peak loads without stalling is essential, particularly when moving heavy materials or navigating steep inclines. A gearbox with a high torque margin ensures the machine can maintain consistent performance even under extreme stress.

Gear Ratio: Gear ratios influence the balance between speed and power. A carefully optimized gear ratio allows machines to maintain steady travel speeds while delivering sufficient force to manage challenging terrain. Choosing the right gear ratio for specific site conditions can be the difference between smooth operation and frequent slowdowns.

Thermal Capacity: Heavy-duty earth-moving machinery generates significant heat, and travel gearboxes must dissipate it efficiently. Gearboxes with superior thermal capacity endure longer operational cycles without overheating, reducing downtime and maintenance costs.

Sealing Class: Robust sealing protects internal components from dust, mud, and debris, which are common on construction sites. High-quality seals prevent premature wear, corrosion, and contamination, significantly extending the service life of the gearbox.

Service Interval and Maintenance Ease: The frequency of required maintenance impacts productivity. Gearboxes with longer service intervals and easy access for routine inspections minimize machine downtime, enabling longer operational hours on site.

At LB, we integrate these specifications into every travel gearbox we produce. Our gearboxes are engineered to deliver optimal torque, enhanced heat management, and durable sealing, ensuring consistent performance across a wide range of challenging jobsite conditions. By focusing on these core performance factors, LB’s travel gearboxes help operators maintain a high level of productivity while minimizing unexpected interruptions.

Understanding how different site conditions affect machinery performance is key to selecting the right travel gearbox. Each environment presents unique challenges that require specific gearbox characteristics:

Muddy or Soft Terrain: In sites with loose soil or wet conditions, traction is the primary concern. Machines are prone to track slippage, which wastes energy and slows progress. Travel gearboxes with high torque margins and reinforced sealing ensure that the machine maintains control, even in sticky or slippery conditions. Sealing prevents mud and moisture from entering the gearbox, which can lead to premature wear and reduce reliability.

Steep or Uneven Terrain: Sites with significant gradients or uneven ground require gearboxes optimized for both torque and gear ratio. Machines must generate enough force to climb inclines without overloading the system. Thermal management becomes critical, as prolonged operation under high torque loads can cause overheating and damage. Gearboxes designed for such conditions maintain consistent output and prevent loss of operational efficiency.

Heavy-Haul Operations: When machines carry heavy loads, both torque capacity and thermal efficiency are essential. Gearboxes must handle sustained high torque without compromising durability or machine stability. Proper gear ratios ensure smooth, controlled movement under extreme load conditions, reducing wear on both the gearbox and tracks, and maintaining consistent project progress.

By matching gearbox specifications to the challenges of specific jobsite environments, fleet managers can strategically prioritize upgrades that deliver measurable productivity gains.

LB travel gearboxes incorporate advanced design features that directly translate into improved on-site performance. High torque capacity allows machinery to handle peak loads without stalling, even on steep slopes or while hauling heavy materials. Reinforced sealing protects internal components from dirt, dust, and water, significantly reducing maintenance frequency and downtime. Thermal management systems are carefully engineered to dissipate heat efficiently, ensuring consistent performance even during extended operational periods.

Each gearbox undergoes rigorous endurance testing that simulates years of operation under extreme conditions, including heavy loads, muddy terrain, and prolonged uphill travel. These tests verify the gearbox’s ability to maintain torque, prevent overheating, and operate reliably without premature wear. By validating performance under real-world stress scenarios, LB ensures that our travel gearboxes deliver measurable gains in uptime, fuel efficiency, and overall operational productivity.

Operators and fleet managers can see tangible results in reduced downtime, smoother operation, and faster completion of tasks. The combination of technical precision, durability, and reliability ensures that LB travel gearboxes provide measurable improvements in both efficiency and operator confidence.

The benefits of a high-performance travel gearbox extend beyond individual machines to the entire fleet. Reduced downtime translates directly into higher overall equipment availability, allowing more machines to be operational at any given time. Efficient torque and gear management reduce fuel consumption by minimizing wasted energy due to track slippage or excessive braking. This not only lowers operational costs but also contributes to more environmentally responsible operations.

Operator confidence is another crucial benefit. Machines that respond predictably under load and maintain smooth movement on difficult terrain allow operators to work more efficiently and safely. Reduced stress from equipment failure or slowdowns improves operator performance, enabling faster task completion while minimizing the risk of accidents. High-quality travel gearboxes thus create a positive feedback loop: reliable machines improve operator performance, which in turn boosts productivity and project outcomes.

Upgrading a fleet with new travel gearboxes requires strategic planning to maximize benefits while minimizing disruption. A phased approach is recommended, starting with machines that experience the highest downtime or work in the most demanding conditions. By replacing travel gearboxes incrementally, fleet managers can maintain continuous operations while evaluating the effectiveness of new components.

Key performance indicators (KPIs) to monitor include time to complete standard hauls, total downtime hours, and fuel consumption per task. Tracking these metrics before and after upgrades provides measurable evidence of performance improvements. Additionally, monitoring maintenance frequency and service intervals helps determine the long-term benefits of the upgrade. By carefully tracking these metrics, fleet managers can optimize investment decisions, prioritize future upgrades, and ensure that all machinery consistently meets productivity goals.

Selecting the right travel gearbox is more than a technical choice—it’s a productivity strategy that impacts every aspect of jobsite operations. With LB’s high-performance travel reducers, machinery can handle tough terrains, heavy loads, and prolonged operations with confidence and reliability. Operators enjoy smoother control, reduced downtime, and faster project completion, while fleet managers benefit from measurable improvements in efficiency, fuel use, and overall uptime. Investing in superior travel gearboxes ensures that your fleet remains competitive and capable of meeting the demands of even the most challenging jobsites. Contact us today to explore LB’s travel reducer solutions and request detailed test data to see firsthand how our components can elevate your on-site productivity.

Q1: How does a travel gearbox affect machine efficiency?

A travel gearbox optimizes torque distribution and gear ratios, ensuring machinery moves smoothly and maintains speed under heavy loads, directly improving operational efficiency.

Q2: Which jobsite environments benefit most from upgraded travel gearboxes?

Muddy, steep, and heavy-haul sites benefit most because high torque, advanced sealing, and thermal management prevent slippage and minimize downtime.

Q3: How can fleet managers measure productivity gains from travel gearbox upgrades?

KPIs such as downtime hours, fuel consumption per task, and time to complete standard hauls provide clear evidence of performance improvements.

Q4: What features make LB travel gearboxes suitable for tough jobsites?

Key features include high torque capacity, durable sealing, thermal efficiency, and endurance testing, ensuring reliable operation under extreme conditions.